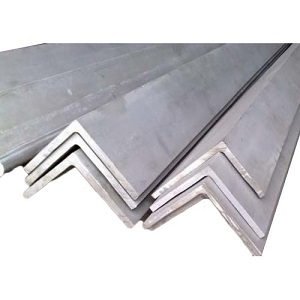

Stainless Steel 321/321H Flats Angles

Mahalaxmi Steel delivers Stainless Steel 321/321H Bars usable in different applications to different industries.Alloy 321 (UNS S32100) is a titanium stabilized austenitic stainless steel with good general corrosion resistance. It has excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800 – 1500°F (427 – 816°C). The alloy resists oxidation to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304 and 304L. It also possesses good low temperature toughness.

Stainless Steel 321 Bars are the most demanded products from our range. We offer these 321H Bars in various standards and sizes to meet customer specific requirements. We have a broad range of Stainless Steel 321 Bars that we manufacture, trade supply, as well as export to our customers worldwide.

321/321H Stainless steel flat Angles is used for general fabrication, making structures and frames. 321/321H Stainless steel flat bar can be easily cut and drilled, and is particularly suited to welding. Examples of its use include furniture making, machinery manufacturing, shipbuilding, railway spare parts, iron towers, steel structures, and boilers.

Due to its anti-corrosive properties, stainless steel 321 bars have become essential in the manufacturing of parts for the medical, tooling, mechanical, engineering and food industries.

-

303 stainless steel bars- has good corrosion resistance, free machining, not suitable for welding or forming.

-

304 stainless steel bars – has good corrosion resistance, suitable for forming and welding, average machining.

-

316 stainless steel bars – Is our highest grade and has excellent corrosion resistance, is suitable for forming and welding, but is a little harder to machine

Stainless steel is one of the most widely used and versatile type of steel. Stainless steel is often referred to as ‘corrosion-resistant steel’ – it does not stain, corrode or rust as easily as normal carbon steel. There are more than 60 grades of stainless steel and divided into five families.

Stainless Steel 321/321H Flat Angles, SS 321/321HH Rectangular Angles vendors, Buy 321/321HH Stainless Steel Threaded Rod, SS 321/321H Triangle Angles, DIN 1.4541 Round Profile Angles, DIN 1.4878 Stainless Steel Polished Round Angles Stockyard, SS 321/321HH Smooth Turned Round Angles, SS 321/321H Rough Turned Bar, Stainless steel 321/321H Peeled Round Bar, SUS 321/321H SS Threaded Rods, 321/321HH Stainless Steel Octagonal Angles, AISI 321/321H SS Welding Rods, Stainless Steel 321/321H/321/321HH Angles Manufactures in Mumbai India, Stainless Steel Round Angles, Stainless Steel Round Rods, SS Angles Stockholders, SS Rods Stockists, Cheap Steel Round Angles, Stainless Steel 321/321H Round Angles, Exporters of SS 321/321HH Forged Round Angles, SS 321/321H Bright Angles, Austenitic stainless steel 321/321HH Black Round Angles, ASTM A276 Stainless Steel Angles Traders, ASME SA276 Stainless Steel 321/321H Square Bar, Wrought Steel Angles, ASTM A479 Grade 321/321HH SS hot finished hexagon Rods, ASME SA479 cold finished stainless steel 321/321HH Hex Angles, Lowest Price ASTM A484 wrought stainless steel bars wholesalers, UNS S321/321H00 Cold Drawn Angles, Suppliers of UNS S321/321H09 Hot Rolled Round Angles Distributors in Maharashtra, SS 321/321H/321/321HH Half Round Angles.

Stainless Steel 321/321H Angles Specification

Standard |

ASTM A276 / A479, ASME SA276 / A479 |

Round Bar Size |

3mm~ 800mm |

Square Bar Size |

4mm* 4mm ~100mm* 100mm |

Flat Bar Size |

2mm ~ 100mm |

Hex Bar Size |

2mm ~ 100mm |

Angle Size |

3mm* 20mm* 20mm~ 12mm* 100mm* 100mm |

Thickness |

50 mm to 6000 mm Long |

Length |

1 To 6 Meters, Custom Cut Length |

Form |

Round, Square, Hex(A/F), Rectangle, Billet, Ingot, Forging Etc |

Chemical Composition

Grade |

C |

Mn |

Si |

P |

S |

Cr |

N |

Ni |

Ti |

SS 321 |

0.08 max |

2.0 max |

1.0 max |

0.045 max |

0.030 max |

17.00 – 19.00 |

0.10 max |

9.00 – 12.00 |

5(C+N) – 0.70 max |

SS 321H |

0.04 – 0.10 |

2.0 max |

1.0 max |

0.045 max |

0.030 max |

17.00 – 19.00 |

0.10 max |

9.00 – 12.00 |

4(C+N) – 0.70 max |