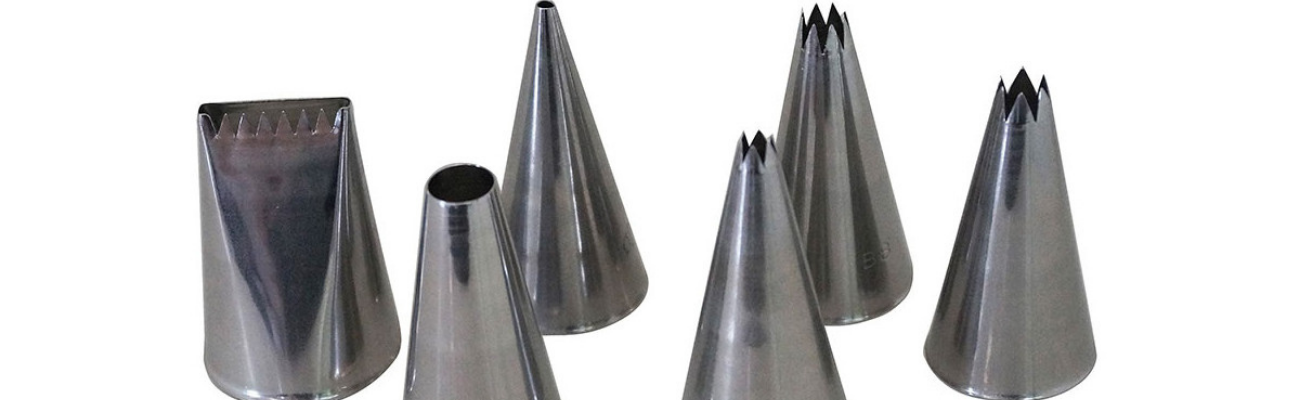

Stainless Steel Shells

Mahalaxmi Steel provides a high-performance solution suitable for both harsh and hygiene necessary environments. These high-quality Stainless Steel Shells deliver superior performance, cost savings, and reduced downtime. This combination, in turn, delivers a lower overall cost of ownership for our customers. Mahalaxmi Steel’s high-quality stainless steel fittings are suitable for the toughest environments such as marine, food processing, and winemaking.

Stainless Steel Shells are non-magnetic in the annealed situation and by cold working operation, it becomes magnetic. Stainless Steel Shells are having oxidation at the temperature of 899 Deg C constantly without scaling. It is a low carbon variety and is used frequently as the as-welded condition at a severe corrosive atmosphere. Stainless Steel Shells is having high carbon in them thus making them ideal for use in applications that need high temperatures.

The manufacturing of Stainless Steel Shells is done under the strict supervision of the professional expert team. They at all levels of production of pipe fittings are guiding the workers to bring out the high quality of the product that assures reliability and longevity. The quality control team is also available that is helping in maintaining the product quality to make sure that no poor quality of pipes is developed.

Specifications for Specification And Material Grade Of Stainless Steel Shells

Mahalaxmi Steel is a leading manufacturer and exporter of Stainless Steel Shells in India. Our inventory includes stainless steel pipes and tubes in many grades including SUS201, SUS202, SUS301, SUS304, SUS304L, SUS304N1, SUS304N2, SUS304LN, SUS305, SUS309S, SUS310S, SUS316, SUS316Ti, SUS316L, SUS316N, SUS316LN, SUS316J1, SUS316J1L, SUS317, SUS317L, SUS321, SUS347, SUS329J1, SUS329J3L, SUS405, SUH409, SUS410L, SUS430, SUS434, –, SUS444, SUS403, SUS410, SUS420J1, SUS420J2, SUS440A. Stainless Steel Shells are readily available in all standard pipe sizes and schedules including Sch 5, Sch 10, Sch 40s, and Sch 80s.

| BRAND | TU-LOK |

|---|---|

| DESIGN STANDARD | DIN 2353/ ISO 8434-1 |

| MATERIAL | SS 304 ,SS 304L , SS 316 ,SS 316L, SS 316TI ( 1.4571) , SS 310, SS 347 |

| SERIES | LL- LOW PRESSURE , L- MEDIUM PRESSURE, S- HIGH PRESSURE |

| WORKING PRESSURE | (LOW) LL SERIES - 100 BAR (MEDIUM)L SERIES - 100 BAR TO 500 BAR (HEAVY)S SERIES - 200 BAR TO 800 BAR |

| SIZE RANGE | LL SERIES - 4LL TO 12LL

L SERIES - 6L TO 42L S SERIES - 6S TO 38S |

| CONNECTIONS | TUBE TO TUBE , TUBE TO MALE THREAD , TUBE TO FEMALE THREAD , TUBE TO BUTT WELD , TUBE TO SOCKET WELD , TUBE TO JIC 37* , TUBE TO 24* CONE, TUBE TO SWIVEL END , TUBE TO ADJUSTBALE STANDPIPE WELD NIPPLE TO MALE THREAD , WELD NIPPLE TO FEMALE THREAD , WELD NIPPLE TO BUTT WELD , WELD NIPPLE TO SOCKET WELD , WELD NIPPLE TO 24* CONE , WELD NIPPLE TO 37* JIC , WELD NIPPLE TO SWIVEL |

| BODY TYPE | FORGED, BAR STOCK |

| SURFACE | STAINLESS STEEL - EXPORT BRIGHT FINISH, SHORT BLASTED FINISH, ELECTROPLATED FINISH |

| TEMPERATURE | (-60*C TO 400*C) |

| EQUIVALENT BRANDS | PARKER, HY-LOK , DK-LOK , STAUFF, HYDAC , VOSS |

| APPLICATIONS & INDUSTRIES | CONSTRUCTION EQUIPMENTS , DRILLING PLATFORMS, HYDRO POWER PLANTS , MACHINE TOOLS , RAILWAY TECHNOLOGY , SHIPBUILDING , WIND TUBRINE , MOBILE HYDRAULIC EQUIPMENT , MINNING , STATIONARY HYDRAULIC EQUIPMENT, INDUSTRIAL HYDRAULICS, INJECTION MOULDING MACHINERY , ALUMINUM DIE-CASTING MACHINERY, SINTERING MACHINERY, STEEL MILLS, HYDRAULIC PRESSES, PAPER PROCESSING MOBILE HYDRAULICS, BUILDING MACHINERY, AGRICULTURAL FORESTRY, LIFTING & MATERIAL HANDLING EQUIPMENT |

| MATERIAL DESIGNATOR | STAINLESS STEEL - ASTM A 276 , ASTM 182 |

TYPES OF Stainless Steel Shells