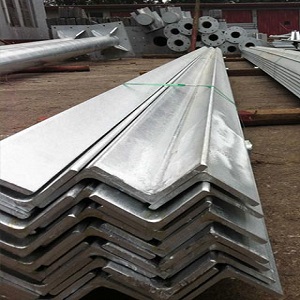

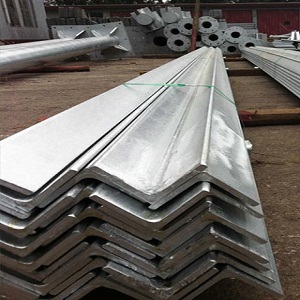

Stainless Steel 316/316L/316H/316Ti Flats Angles

Mahalaxmi Steel is a known exporter of Stainless Steel 316 flats, where post-weld annealing is not required when welding thin sections. Stainless Steel 316 Sheets is a chromium-nickel-molybdenum austenitic stainless steel developed to provide improved corrosion resistance to Alloy 304 / 304L in moderately corrosive environments. Stainless Steel 316 Plates are often used in biomedical implants, chemical processing, pharmaceutical, textile finishing, food processing, photographic, marine exterior trim, etc.

The main advantage of Stainless Steel 316 Coils over grade 304 is its increased ability to resist pitting and crevice corrosion in warm chloride environments. Stainless steel cylinders and tanks are manufactured in 316 Stainless Steel Sheets, Plates have proved to offer exceptional resistance in acidic and hard water areas. The low carbon chemistry of Stainless Steel 316L Sheets combined with an addition of nitrogen enables the alloy to meet the mechanical properties of Alloy 316.

Stainless steel 316 is an austenitic steel with excellent welding and forming characteristics. It is the second most commonly used stainless steel and represents around 20% of the entire world’s production of stainless steel.

The key element that differentiates it from most other stainless steels is the inclusion of molybdenum, between 2% and 3%, which enhances its resistance corrosion in general and pitting corrosion in particular.

It is malleable and ductile and has good weldability. Its austenitic structure allows it to be deep drawn without intermediate annealing. It is also unnecessary to anneal it following welding thin sections.

However, the inclusion of molybdenum may have some adverse effects on its formability.

It is widely used in:

-

Chemical processing and storage equipment.

-

Refinery equipment

-

Medical devices

-

Marine environments, especially those with chlorides present

In its annealed state it is virtually non-magnetic even when cold worked, unlike 304 which can be significantly attracted to a magnet after cold working. This may make it more suitable in some applications.

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

SS 316 |

1.4401 / 1.4436 |

S31600 |

SUS 316 |

316S31 / 316S33 |

– |

Z7CND17-11-02 |

X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

SS 316L |

1.4404 / 1.4435 |

S31603 |

SUS 316L |

316S11 / 316S13 |

03Ch17N14M3 / 03Ch17N14M2 |

Z3CND17-11-02 / Z3CND18-14-03 |

X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

SS 316H |

1.4401 |

S31609 |

– |

– |

– |

– |

– |

SS 316Ti |

1.4571 |

S31635 |

SUS 316Ti |

320S31 |

08Ch17N13M2T |

Z6CNDT17-123 |

X6CrNiMoTi17-12-2 |

Specification

Standard: ASME, ASTM, EN, BS, GB, DIN, JIS, etc

Material: Industrial Grade Stainless Steel

Length Flat : 2 meters – 7 meters ( 8 feet to 24 feet)

Flat Size Range: 38×10 mm to 150×25 mm

Angle Size: 3/4″ THRU 8″

Angle Thickness: 1/8″ thru 5/8″

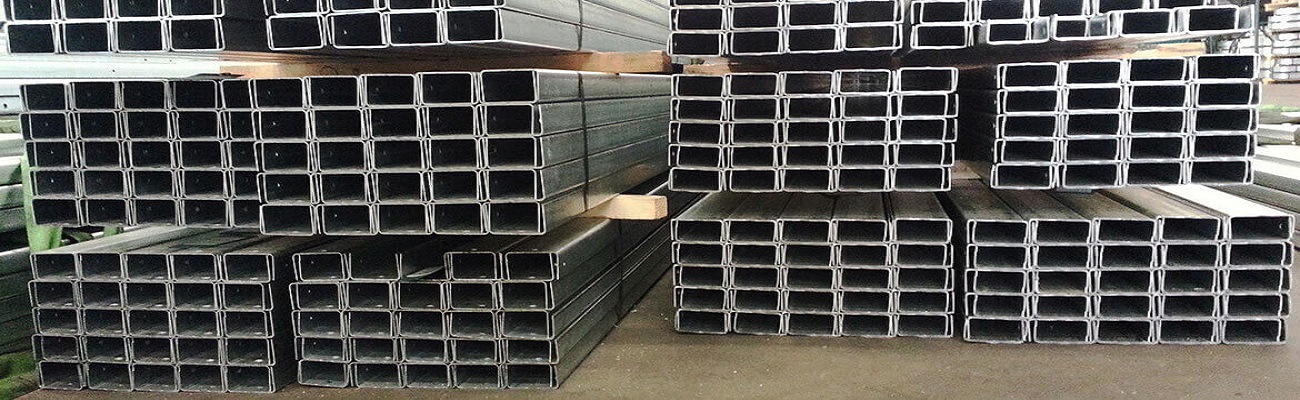

Channels Size: 30mm*15mm*15mm*1mm-300mm*150mm*150mm*30mm

Channels Diameter : 50x37x5mm

Angle: Structural Steel Angle, Equal, Unequal, L, T, Hot Rolled,

Channels: Structural Steel U, C, Miscellaneous Channels, Hot Rolled Channels

Flat : Bright, Black, Polish Flat

Condition: Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Stainless Steel 316 Flats Angles

| AISI | EN / DIN | ASTM/UNS | EN | AFNOR | Reg.TM | Forging | |

| 316 | 1. 4401 | S31600 | X5CrNiMo17.12.2 | Z7CND17.11.02 | NA | A182 F316 | Austenite |

| 316L | 1. 4404 | S31603 | X2CrNiMo17.13.2 | Z3CND18.12.02 | NA | A182 F316L | Austenite |

Stainless Steel 316 Flats Angles are characterized by improved corrosion resistance in most acidic conditions, especially at higher temperatures and/or with chlorides present. Among 316 and 316L Flats Angles is more preferred for welded constructions. We are leading suppliers of “Dual Certified” Stainless Steel Flats Angles meeting the requirements of both 316 and 316L.

Mahalaxmi Steel is an ISO 9001: 2008 Certified manufacturer and supplier of Stainless Steel 316 Flats Angles, with a supply base to all destinations in India and worldwide. Metline stocks and supplies a full range of Stainless Steel 316 Flats Angles from 8mm diameter to 600 mm Flats Angles with 1 meter to 6 meters length.

We specialize in the export of a wide range of Stainless Steel 316 Flats Angles stock products such as Steel Rounds, Squares, Hexagons, Bright Flats Angles of various grades which are used as raw material by various manufacturers in engineering, forging, oil, and gas components, drilling materials, tools & dies, as well as auto component industry.

Stainless Steel 316 is the standard molybdenum-bearing grade, second in importance to SS 304 amongst the austenitic stainless steels. The molybdenum gives SS 316 better overall corrosion resistant properties than Stainless Steel 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. Stainless Steel 316 has excellent forming and welding characteristics. It is readily braking or roll-formed into a variety of parts for applications in the industrial, architectural, and transportation fields. SS 316 also has outstanding welding characteristics. Post-weld annealing is not required when welding thin sections.

SS 316L, the low carbon version of SS 316 and is immune from sensitization (grain boundary carbide precipitation).SS 316H, with its higher carbon content, has application at elevated temperatures, same as SS 316Ti which is a Titanium stabilized grade. SS 316N is a nitrogen enhanced with greater strength than SS 316.